|

Fogged RV Window do-it-yourself clearing process |

|

|

|

|

|||||||

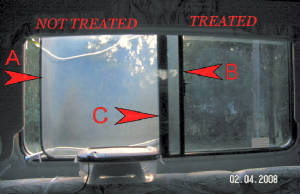

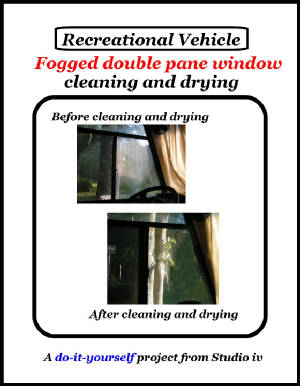

UPDATED April 14, 2015 We developed a "double pane inner space washing/drying

process" that we want to share with others in the fogged window club. Our process will give you clear windows again until

you have an opportunity to travel to one of the refurbishing facilities. The photos on this page are our windows. The results

are more dramatic than shown. Eventually a double pane window’s seal system will fail. As the inner space heats

up, the inner air expands and is forced out of the compromised seal system. When the inner space air cools and contracts,

humidity-laden air is drawn in bringing baggage with it that is deposited on the interior glass surfaces (usually turning

into a white cloud look). RV failures seem to be between four and seven years. Five of our Class A double pane windows, including

the drivers' side window fogged. Driving safety was compromised by the milky side window. Everywhere we turned we heard the

same answer: "you will have to bring the coach to our facility and either replace them or have them dismantled and refurbished."

We thought that there must be a way to have clear windows without spending hundreds of dollars. Additionally the trip would

involve several days. Our 14 page Copyrighted process

description includes easy to follow step-by-step illustrated instructions about building your system, materials lists including

parts numbers, where to purchase suggestions, cautions, tips and on-going assistance via email. What you will be creating

is an inexpensive and easy to use portable "inner-space" residue removal and moisture maintenance system. This process

will not provide a permanent fix for the majority of users. Mini re-fogging may occur and look like "breath on glass".

You can easily remove that moisture and have a clear window again in minutes, even at a camp site. Our manual is updated as

we receive tips from users. Recently a South Floridian shared his modifications that were required to clear three large picture

windows. Our process was featured in the FMCA magazine New Products, October

2009. We are pleased to give you encouragement that a clear window again is possible. We wish that we did not have to

charge for this material however getting the word out is surprisingly expensive. We will be available by email to assist you

through the process if needed. Until you do something about your fogged window we suggest that you: 1. Shield your

fogged window(s)s from direct sun as much as possible. Don't allow the sun to continue baking the baggage that the moisture

drags into your double pane inner space. Irreversible surface corrosion can result. 2. Clean out the window drain holes

- you don't want your damaged window seals sitting in pools of water. Contact us if you have any questions now and

anytime after you receive the materials.

. |

Please click here to contact us at Studioiv. |

||||||

|

.. ...

|

|||||||